Usually, plain concrete is used for constructing pavements, footpaths and buildings in areas that do not require high tensile strength.

The density of this concrete is between 22 kg/cubic metre, whereas its compressive strength is in the range of 200 to 500 kg/square centimetres. The most commonly used mix is cement, aggregates and water in the proportion 1:2:4. Plain concrete – It is the simplest kind of concrete that does not require any reinforcement. Typically, there are twenty-four different types of concrete used in the building and construction industry depending on the type of construction.

#Foam concrete mix design calculator free

Reach out to Top Concrete dealers near you and get free quotesĭifferent types of concrete and their applications As long as there are construction activities going on in the world, there will be a constant demand for concrete. One can use crushed recycled concrete as the dry aggregate for preparing new concrete. Hence, it is environmentally friendly and recyclable. This flexibility and versatility make concrete the most sought-after construction material in the world.Ĭoncrete is manufactured using natural ingredients. Secondly, concrete is inexpensive and mouldable into various shapes.

Firstly, the use of concrete is important in modern-day construction because the structures derive their strength and stability from concrete. In short, wherever there is a structure, there is concrete. It is used in the construction of huge buildings, bridges, roads, sidewalks, flooring and literally everything our eyes can see. Why is concrete important in modern-day construction?Īs you walk around on the road, you can see concrete everywhere. On the other hand, mortar uses sand as the sole aggregate. Concrete is a mix of sand (fine aggregate), cement, gravel or crushed stone (coarse aggregate) and water. The primary distinction between mortar and concrete is that the latter is stronger than the former. Elastizell concentrate is designed to resist the physical and chemical forces imposed during mixing, pumping and placing.In the olden days, mortar was widely used for construction purposes, whereas concrete is the principal ingredient today.

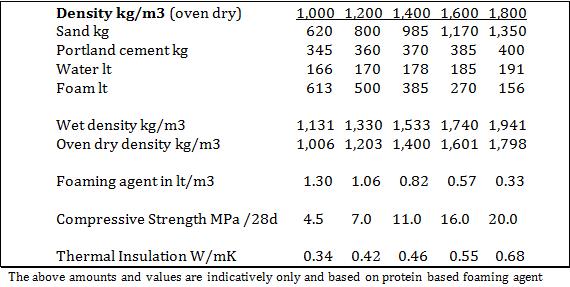

These air cells are coated with cement paste which upon setting results in a discrete cell structure. The foam volume controls the density of the concrete by creating stable air cells within the concrete mixture. This solution passes through a specially designed foam nozzle and combines with pressurized air which expands the solution producing a foam with the appearance of shaving cream.Ī predetermined quantity of preformed foam is added to a concrete slurry or grout while mixing to produce cellular concrete. These concretes are usually pumped into place and finished prior to setting.Įlastizell preformed foam is created by first diluting one part Elastizell concentrate with 40 parts water. Elastizell cellular concrete may be designed for densities varying from 20-120 pcf. Designs utilizing fly ash, sand and other materials may be included for specific densities, properties and strengths. Elastizell concrete is typically a mixture of cement, water and preformed foam.

0 kommentar(er)

0 kommentar(er)